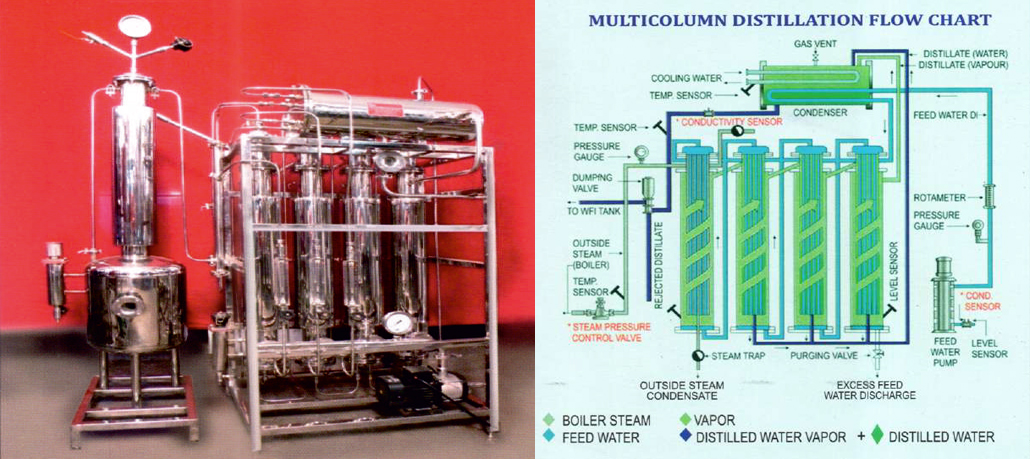

MULTICOLUMN DISTILLATION PLANT

NITIN’S Multi Column Distillation Plant is based on the principal of interstate heat exchange to produce pure pyrogen free sterile distilled water. A part of feed water on the inside of the heat exchanger tubes is converted to steam because of surface film evaporation. A predetermined minimum amount passes through the column which causes both rapid heating of feed water & rapid cooling of boiler steam, therefore creating vapors at high velocity under pressure. This vapor rising through the entertained section is subjected to a 180 turn caused by centrifugal force. Due to spiraling motion, the pure vapor rises upward through a vertical section outside the heat exchanger. Due to this unique centrifugal separation technique, the impurities such as endotoxins and Pyrogen are removed. The purified steam then moves towards the upper portion of the column. The pure steam in the first column serves as the source of heat for the second column. This process is repeated in all the 4 to 5 columns or more. Each column is working at a slightly lower temperature and pressure than the proceeding one. The heating energy requirements are reduced by 70% as external heat is requires to vaporize only 30% of the feed water.

Design Features

Panel board with PLC, Microprocessor controls, facilitate self regulation and self monitoring except for 80 litre still.

- Positive air/gas venting to ensure pure distillate.

- Centrifugal Feed Pump fabricated with type 316 SS.

- A SS Centrifugal Pump for cooling water transfer.

- Electro polished cervicalis, inner contact surfaces.

- Improvised cooler design for optimum efficiency.

- Maximum pressure 8-10kg/cm² .

- Conductivity meter for feed water and final distillate.

Optional Acessories

- D.M. water storage tank with Float Control to maintain level of feed water.

- Steam pressure reducing station with diaphragm type valve to adjust the steam pressure from 2 Kg/cm² to 7 Kg/cm² with an indicating pressure gauge.

Technical Specifications

- Distillate : Meets I.P./B.P. Specifications.

- Temperature: 95°C.

- Conductivity: Less than 1 Microsiemen/cm.

- Feed Water: De-ionised water with max. conductivity of 5 Microsiemen/cm should be used. Feed Water Pressure-should be 1 Kg/cm higher than the infeed feed pressure. Temperature-ambient 30°C.

- Cooling Water: Normal tap water is used to provide hardness in less than 90 PM of CaCO & sub3.