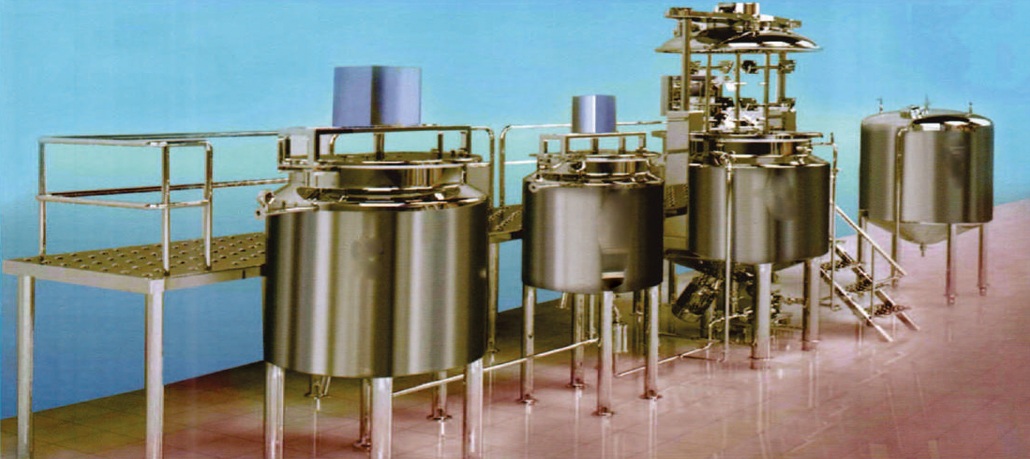

OINTMENT / CREAM PLANT

NITIN Ointenent/ Cream machine that we are offering to the clients is effective, efficient and reliable in all possible conditions. This product is designed by the personnel, having years of experience & expertise in their working areas.

OPERATION SEQUENCE FOR OINTMENT AND

CREAM MANUFACTURING

Ensuring body internals of the works are cleaned thoroughly, Charging of pre-determined water quantity to water phase vessel supply of steam and addition of additives manually and at Preset temperature, Chrging of oil / Petroleum jelly / Wax to oil phase vessel supply of steam heat temperature addition of additives manually and mix at preset temperature Starting homogenizer for emulsification and dispersion vacuum. Transfer the heated oil and heated water to manufacturing vessel. After confirmation of cream/ointment discharge the product to storage tank using lobe pump keeping the product under slow speed cogitation in storage vessel transferring the product to filling through metering pump.

Techinical Speccification

These plants are ideal for the pharmaceutical & cosmetic industries for the production of ointment, cream, lotions, tooth paste and other emulsions & homogenization, specially designed to take care of two critical factors which directly affects the quality of the ointment/creams minimum man handling of ointment/ negligible vacuum drop during mixing-blending provides the benefits of effective manpower utilization.

Equipment and Acessories

Manufacturing vessel or jacketed planetary, Wax phase vessel with top entry stirrer, Water phase vessel with top entry stirrer, Storage vessel, Vacuum pump, Control panel, Product piping, Working platform, Material transfer pump to transfer material from manufacturing vessel and storage vessel to ointment.