BLENDING LINE

DOUBLE CONW BLENDER

We offer a wide range of double cone blenders of superior quality.Our products hom ogeneously mixes the dry powder and granules thus serving various applications in industries like food, dairy, beverage, pharmaceutical, cosmetic and chemical industry. Our range of products are known for their high quality, durable finish standards and flawlessness.

- Uniform mixing and easy discharge is made possible by the conical ends at both the sides

- Right or left side drive as per client’s requirement

- Safe operation is ensured

- Special type of gear is provided for speed reduction

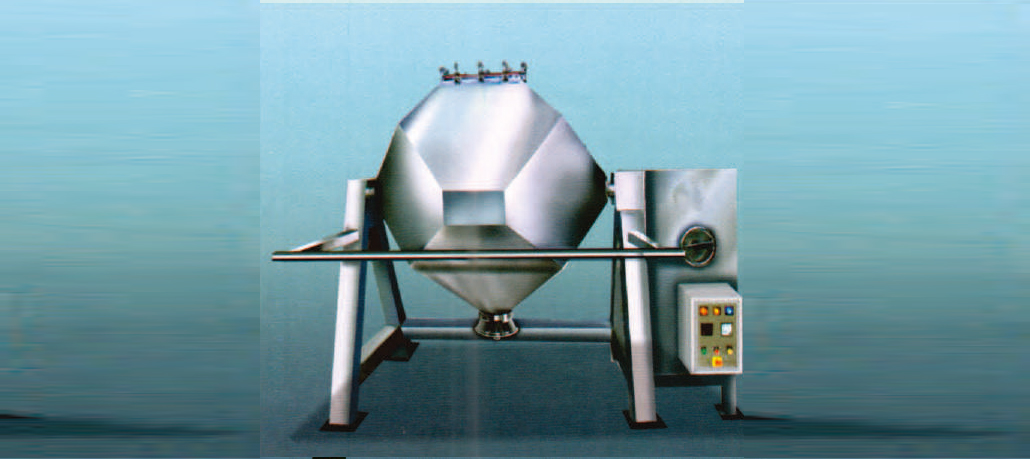

OCTAGONAL BLENDER

The blending machine for mixing and lubrication process of dry granules homogeneously. Two third of the volume of the Cone Blender is filled to ensure proper mixing. It is appropriate for quick and efficient mixing for a entire range of powders, particulate and granular materials. In Octagonal Blender the granules comes from all sides due to the octagonal shape of the product container, hence prerequisite of RPM is less. The octagonal shape & slow speed of rotating gives adequate constant movement to the granules re sulting in good quality.

Salient Features : Contact parts in stainles steel 304 or 316, Octagonal shaped with rectangular center, conical discharge frustum and rectangular top frustum Baffles provided in the shell, Manhole with gasket is provided to fix baffles and for ease of cleaning the shell Charging - discharging

POLYGONAL BLENDER

Polygonal Blenders offered by us is widely appreciated for their ability to offer homogeneous mixing within no time. Designed after extensive researches, our range comes in ultra-modern designs that occupy minimum space and enhances the labour efficiency. Apart from these, the factors that have contributed for a widespread demand of our range include.

Salient Features :

- Ideal for large volume / batch blending.

- Symmetrical with reference to X, Y & Z axes homogeneous mix in shorter time frame.

- Extremely gentle handling of products due to very low rotational speeds.

- Higher loading capacity - 75% of gross volume.

- Most optimum “volume to space occupied ratio.

- Low power consumption easy and total discharge access for thorough cleaning slow speeds-low maintenance